Infrared Thermometers for Food Safety Applications

In the US alone, CDC estimates that approximately 3,000 people die or one in six Americans gets sick from foodborne illnesses. Keeping food safe is the number one priority for restaurant and food business owners. A critical part of ensuring food safety is strict temperature guidelines. Follow the recommended proper temperature monitoring procedures to ensure food safety. If you are a business owner, make sure you have an infrared thermometer to help you accurately determine food temperature.

Table of Contents

Common Food Safety Mistakes and How to Avoid Them

A lot of restaurant and food business owners are guilty of making common food safety mistakes. The worst part is that most are not even aware that they are doing so. Here is a quick guide to these common mistakes so you can be aware.

1. Relying on an infrared thermometer to measure internal food temperature.

An infrared thermometer is recommended for measuring the surface temperature of an object. For example, you can use it to test the temperature of the grill to know if it’s ready for the meat. You may also use it to check the temperature of the food. However, you cannot rely on this cooking tool to determine the accurate temperature reading of the food. For this one, you need a probe thermometer that you can insert into the center of the food to take readings.

Before using an infrared thermometer, it pays to know the limitations of use for this food thermometer. That way, you know when and how to use the various types of thermometers to ensure food safety.

2. Not stirring food when taking temperature.

Another important step in accurately testing the temperature of the food during preparation or cooking is to stir it. Multiple gradients exist in food during the cooking process. The gradients mean that some parts of the food are hotter than others. The uneven temperature can be a huge risk when you are testing the food for safety reasons.

Even if the external part of the food is of the right temperature, the center might not have reached the safe temperature level yet. This means that the center part of the food is cooler than the exterior. Stirring the food ensures the even distribution of heat which will produce a more even and accurate temperature reading with a thermometer.

3. Checking the wrong part of the food.

Using a probe thermometer does not guarantee a correct and accurate reading. Make sure that you know where and how deep to insert the probe.

The best way to check the internal temperature of the meat is to insert the probe into the center of the meat. Make sure to stick the probe into the center of the thickest part of the meat. This step ensures that you can get the reading on the innermost part of the meat. If that part is cooked, then you know that everything else is done.

4. Not testing the thermometer’s accuracy regularly.

It is important to regularly calibrate and test the thermometer for accuracy. If you rely on your thermometer as an important tool for food safety, it must be working properly and accurately. You can perform an ice bath test to check the reading within the accuracy specification for that model of thermometer.

How to Use Infrared Thermometer for Food Safety

Monitoring temperature is a vital part of ensuring food safety. Therefore, an infrared thermometer is the best choice of tool for any cook or food business professional.

It’s clear that infrared, or non-contact thermometers, have their limitations for use in the kitchen. Many cooks rely on probes that are inserted into the food to check for internal temperature. However, infrared thermometers can be just as reliable and helpful in tracking surface temperatures without contact.

Infrared Thermometers Reduce the Risk of Cross-Contamination

Contamination is a serious threat in food preparation and handling. It could happen within the kitchen and using the very tools that are designed to ensure food safety. When chefs are busy in the kitchen, it could be easy to overlook the small details, such as cleaning and drying the thermometer probe. As a result, many use the same tool for checking the temperature of different types of food.

Using the same probe on different food products is a health hazard and a risk for cross-contamination. For this reason, a non-contact process is a more suitable option to limit the risk of cross-contamination and keep food safe.

Handheld IR thermometers accurately and effectively measure food and surface temperature as long as you follow the best practices for using them. At the same time, it is also important for food industry professionals to understand their limitations so they can use them correctly.

Precise Targeting of Items

The ability to precisely target the object or food measured is another advantage of using infrared thermometers. Some IR thermometers feature a laser pointer that correctly identifies the object being measured and avoids confusion in the temperature reading. It makes it easier to scan and read food temperature, especially when moving ingredients and keeping them in mobile food storage.

Use it to Establish Baselines in Monitoring Food Temperature

An infrared thermometer is an invaluable tool for the safe monitoring of food temperature. You can use it to establish the baseline temperature during food storage, food production, and other quality control processes. The ability to quickly scan temperature readings ensures compliance and maintains quality within your supply chain.

Lack of Temperature Draw-Down

Using contact thermometers for testing the food temperature can interfere with food safety monitoring. The actual measurement can introduce changes to food temperature, which risks an inaccurate reading. You must be aware of the temperature draw-down that could happen when using contact thermometers.

Conclusion

Using an infrared thermometer for food safety is a smart decision because this tool delivers quick and accurate readings. You can use it to scan the temperature of your ingredients in food storage facilities or during production. This method ensures that you can maintain the quality of the food and guarantee that it is safe to eat before you serve it.

One Comment

Leave A Comment

Discover more recipes and learn kitchen tricks by joining our cooking family on Facebook.

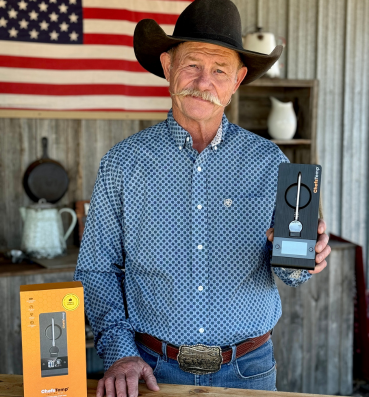

Shop now for products used in this post:

You may also like:

[…] strict food safety regulations, and temperature monitoring is critical. Therefore, you need a thermometer for a food safety check and temperature control or […]